Changing Upkeep with the Transformer Oil Regeneration Process

Changing Upkeep with the Transformer Oil Regeneration Process

Blog Article

Just How Regenerated Transformer Oil Prolongs Transformer Life Expectancy

The role of transformer oil is essential in making sure the reliability and longevity of transformers, serving as both an insulator and coolant. Restored transformer oil supplies a compelling solution to enhance these functions by efficiently removing unsafe impurities that compromise performance. With a meticulous regeneration process, the oil's dielectric buildings and thermal stability can be recovered, leading to considerable renovations in functional efficiency. Comprehending the ins and outs of this process and its more comprehensive effects for transformer upkeep exposes a pathway to not only prolong life-span but likewise maximize prices in power administration systems.

Relevance of Transformer Oil

Transformer oil plays an essential function in the reliable procedure of electric transformers. It primarily works as a shielding tool, guaranteeing and avoiding electrical discharges that parts operate safely under high voltage problems. The oil's dielectric properties are fundamental to preserving the stability of the transformer, as they decrease the risk of failings that can lead to pricey downtimes or disastrous incidents.

In addition to its shielding abilities, transformer oil also functions as a coolant. As transformers run, they generate heat that must be dissipated to avoid overheating and succeeding damages. The oil distributes within the transformer, absorbing and moving warmth away from critical components, therefore maintaining optimal operating temperatures.

Moreover, transformer oil works as a barrier against wetness and contaminants, which can endanger the efficiency and durability of the transformer. Its chemical buildings help in counteracting acids and other results that might form with time, adding to the total health and wellness of the electrical system.

Advantages of Regenerated Oil

Additionally, regenerated transformer oil has a reduced level of pollutants, including particles and pollutants that can break down efficiency. This pureness not only enhances the oil's thermal conductivity but additionally prolongs the functional lifespan of transformers by decreasing overheating risks. The boosted thermal security of regrowed oil guarantees regular performance also under high operating temperatures, which is essential for keeping transformer efficiency.

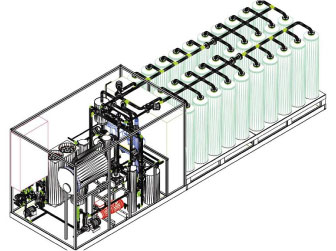

One more benefit is its environmental influence. Regrowed oil advertises sustainability by reducing waste and the need for new oil manufacturing, therefore decreasing the carbon impact related to transformer maintenance. Transformer Oil Regeneration Plant. Furthermore, the long life of regenerated oil translates to lower maintenance prices gradually, as less oil adjustments and less frequent tools downtime are required.

Refine of Oil Regrowth

The regrowth of transformer oil involves a methodical procedure made to recover the oil's original homes and boost its performance. This procedure usually starts with the removal of the utilized oil from the transformer, which is then subjected to numerous purification methods.

The initial step in the regrowth procedure is the filtration, where strong impurities such as metal, dirt, and sludge particles are eliminated. This is commonly adhered to by vacuum cleaner distillation, which aids to eliminate dampness and unstable substances, consequently boosting the oil's dielectric stamina.

Effect On Transformer Performance

Recovering the residential or commercial properties of regenerated transformer oil considerably affects the general efficiency of transformers. Enhanced dielectric strength is just one of one of the most critical benefits, as it enables better insulation and lowers the chance of electrical failure. This improvement leads to an extra secure procedure under high voltage conditions, ultimately resulting in boosted efficiency.

Additionally, the elimination of impurities and degradation items during the regeneration procedure reduces the risk of overheating. Cleaner oil facilitates much better warmth dissipation, which is essential for preserving optimal operating temperatures. As an effect, the thermal performance of the transformer is boosted, permitting greater loads without jeopardizing dependability.

In addition, the chemical stability of regenerated oil makes certain prolonged functional life. It stands up to oxidation and deterioration, decreasing the frequency of maintenance interventions and oil substitute. This stability not only adds to enhanced performance but also straightens with sustainability objectives by decreasing waste.

Future of Transformer Maintenance

As advancements in innovation continue to improve the landscape of electrical design, the future of transformer upkeep is poised for significant transformation. The assimilation of wise innovations, such as IoT sensors and predictive analytics, allows real-time surveillance of transformer health, improving the capacity to preemptively address concerns prior to they escalate into major failings. This aggressive strategy not just maximizes functional efficiency however also prolongs the lifespan of transformers.

In addition, the application of expert system (AI) in information analysis enables more exact linked here mistake detection and medical diagnosis. By leveraging equipment understanding formulas, maintenance groups can identify patterns in operational information that human analysts might ignore, leading to more enlightened decision-making.

In addition, the adoption of eco-friendly practices, including making use of regenerated transformer oil, is established to redefine maintenance protocols. This lasting strategy not just lessens environmental effect but also boosts the general wellness of the transformer.

Finally, the shift in the direction of automation in upkeep processes is expected to improve operations, lower downtime, and lower expenses. As these developments remain to develop, the future of transformer look at this now upkeep will unquestionably become extra efficient, reliable, and sustainable, making sure the integrity of vital electrical framework.

Conclusion

The utilization of regenerated transformer oil dramatically enhances the operational durability of transformers. Eventually, the fostering of restored oil stands for a critical improvement in transformer upkeep, making sure ideal efficiency and sustainability in the management of electric infrastructure.

The role of transformer oil is crucial in making certain the dependability and long life of transformers, serving as both an insulator and coolant.Transformer oil plays a crucial role in the efficient procedure of electrical transformers. Restored oil promotes sustainability by decreasing waste and try this web-site the need for new oil manufacturing, thereby decreasing the carbon impact linked with transformer maintenance.Restoring the residential properties of regenerated transformer oil significantly affects the overall efficiency of transformers.The application of regenerated transformer oil dramatically improves the functional long life of transformers.

Report this page